The engineers at Rockwell Automation designed and developed the A Great Flying Machine that name was Star Raker, a space aircraft that is used in the Satellite Power Station (SPS) program to solve the energy problem of the United States. Today, we will discuss the story of this great flying machine.

Introduction:

The Rockwell Star Raker is an iconic symbol of midcentury aerospace ingenuity, reflecting the soul of a bygone era’s space exploration fantasies. The Star Raker, designed in the 1960s as a single-stage-to-orbit spaceplane, aimed to transform space travel by seamlessly transitioning between the Earth’s atmosphere and outer space. Rockwell International’s innovative concept aimed to combine the efficiency of an Aeroplan with the capabilities of a spacecraft. With its sleek form and cutting-edge engineering, the Star Raker promised to usher in a new era of space exploration and transit. The project was never completed but its legacy remains as a tribute to bold aeronautical goals. This introduction delves into the fascinating story of the Rockwell Star Raker, a groundbreaking concept that has left an indelible mark on the history of space exploration.

A Great Flying Machine: Rockwell Automation Detail Story:

History of Rockwell Star Raker:

On a cold February morning in 2000, the Californian skies have been cleared for a very special flight. The A Great Flying Machine: The Rockwell Automation of Star Raker with 12 supersonic turbo jets rolls out onto the desert runway. The crew double-checked its urgent cargo is secure components for a 70000 Tons solar power plant destined to skim the atmosphere in low orbit above the earth.

For this colossal monster, this mission would be the first of many flights this year. One of 25 years of operations planned to build a ring of 60 orbital power stations to solve the United State’s energy crisis. At 8:36 am, President Al Gore has approved the flight and the tower has authorized take-off. The captain gives the command to go with throttle up and the Rockwell International Star Raker takes to the sky.

This alternative history never happened, breaking the sound barrier at Mach 6. This 12 engines turbo turbojet’s spaceplane would have ushered in a new age of space exploration and made even the most impressive SpaceX rocket obsolete, but the legendary star plane would never be built. Today, its possessor the space shuttle is no more. what was the star raker? how did it fly? and why did the United States decide to never build it grab your oxygen?

Now we move to low earth orbit, In the 1970s United State faced increasingly worst energy shortages, according to news “when the demand grows greater than the immediate supply and the circuits break tension passengers flight-307 is cancelled, until further notice”. Its main source of petroleum had ground to a halt, thanks to the international crisis in Iran and the Middle East and nuclear had been ruled out after two high-profile nuclear meltdowns.

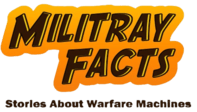

Project of Satellite Power System (SPS):

By 1977, the threat of running out of energy had gripped, the U.S nation with President Carter declaring “then we must start now to develop the new unconventional sources of energy that we will rely on in the next century” and the solar power plant would they come up with something that would tick the unconventional box. NASA pitched a series of 60 gigantic geosynchronous satellites orbiting the planet beaming down refined energy for the world’s use. It was called the satellite power system (SPS) and would be comprised of a global network of giant photovoltaic arrays. The Solar plant in Space was huge with two long solar panel structures five kilometers long by four kilometers wide or 3.1 miles by 2.4 miles for a total of 11.73 kilometers long or 7.2 miles in imperial units, weighing the small amount of 10.42 million kilograms or 22.97 million pounds.

Now you are thinking that doesn’t make any sense. How can we imagine the size of these satellites more realistically? Well, here’s an excellent graphic from Scott from the aerospace projects review that shows off the solar power satellite over New York City. It’s bigger than Manhattan and easily crushes part of the outer burrows as well.

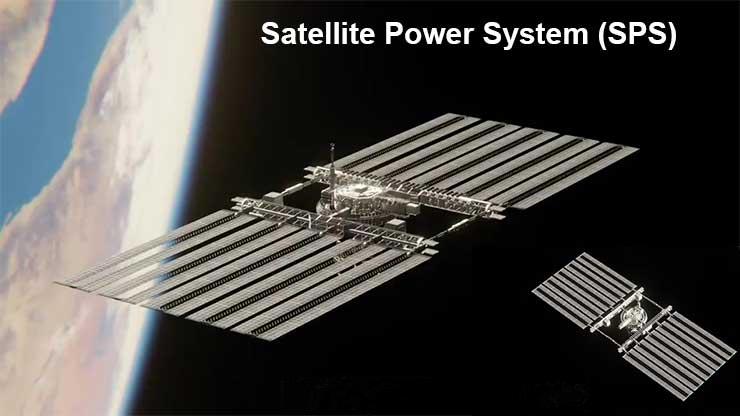

Space Solar Power Plant:

The power station in orbit would eliminate dust and day and night cycles, allowing it to produce energy 24/7. The power would transmit the electricity it generates through microwaves to a thin receiving mesh, which people could build anywhere, even over oceans. This project would take 30 years to realize all 60 units, but it would spawn an incredibly lucrative industry planeside in the United States. The SPS (Satellite Power System) is an attractive challenging and worthy project which the aerospace community is well prepared and able to address.

wrote in support of the project, but the problem was how would NASA even get all of the materials personnel solar panels and more into orbit to build these power stations? so far, they had only launched the 77 metric ton or 85 ton Skylab into low earth orbit using a huge Saturn V rocket left over from the earlier Apollo moon missions.

Structure of Space Solar Power Plant:

The new solar power station weighed a hundred times more than even the modern international space station that we have orbiting today and rockets wouldn’t cut it, it would need over a thousand Saturn V launchers to even get one SPS (Satellite Power System) into earth orbit. So, NASA turned to the market for the solution, the first to reply was Boeing. Boeing proposed several different concepts, but the most significant one they offered was the Space Fighter. The space fighter was Boeing’s pitch to solve the earth to orbit problem of the SPS program. As its name may infer it was a rocket system/space plane that would act like a lorry for space station components for assembly in orbit.

The rocket will consist of two stages.

1. Booster-Stage of Boeing Space Fighter:

Once the launch team expends the main fuel tank, they will leave the Booster stage sitting on the launch pad and launch it towards the east. The booster section that it separated earlier would have also done the same using onboard jet engines to become more plane-like and land on a very wide runway approximately 200 miles away from the launchpad. When the launch site reunited the booster and the orbiter, they reassembled and loaded new goods onto another plane. Many sources glossed over the complexity of this process, but it involves the booster landing approximately 200 miles downrange from the launch site.

Freighter to launch from Nevada/Arizona, land in New Mexico/Texas. Booster transported back by train.

The project would require building a new airport 200 miles downrange and a railway line connecting them both, making it very expensive. They expected to have a fleet of 94 space freighters, with each one flying every five days and a turn around every 36 hours, requiring a stunning 240 space launches a year to achieve the goal of building two SPSS per year. This would quickly lead to the retirement milestone in only four years. It is worth noting that this was only one of many other Satellite Power System launch crafts proposed in the era.

2. Orbiter-Stage of Boeing Space Fighter:

The orbiter would orbit and rendezvous with the station scaffold to unload materials. Each mission carried a payload of 424000 kg or 934,000 lbs. The space fighter would use the remaining fuel to de-orbit and land via a runway.

In 1981, NASA noted that the advanced space transportation program would require long-term routine operations similar to commercial airline and air fight operations.

Rockwell Star Raker Design & Internal Structure:

In the late 70s, Rockwell International realized that they could substantially improve several areas with their ideas for a space fighter. They came up with this the air breather rocket-powered horizontal take-off Tri-delta flying wing single stage to orbit transportation system, today is The Rockwell Automation of Star Racker.

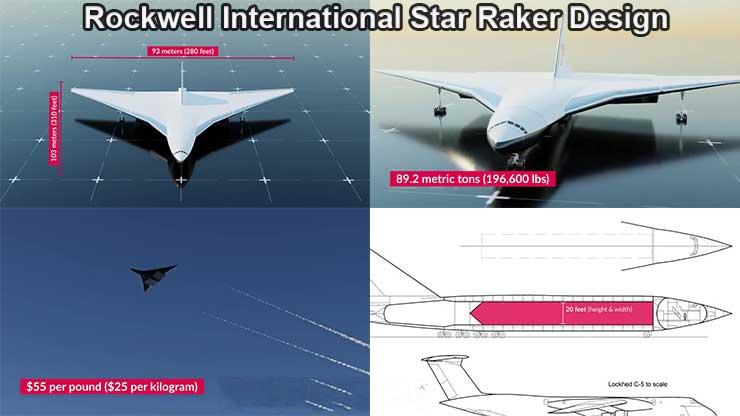

It was a spaceplane that was 103 meters long with a wingspan of 93 meters and would have carried a maximum of 89.2 metric tons of cargo into low earth orbit around 300 nautical miles above the equator or 555 kilometers.

In total, this would allow firms to receive payloads in orbit at a cost of about $15 per pound of $55 per pound., today in metric this is $25 US dollars per kilogram. For comparison’s sake Elon Musk with the SpaceX rockets costs around about $2720 per kilogram to put something into orbit. So, this dream of low-cost orbit delivery is ridiculous and would be a total game-changer. Thanks to this vast Tri-delta wing blended design.

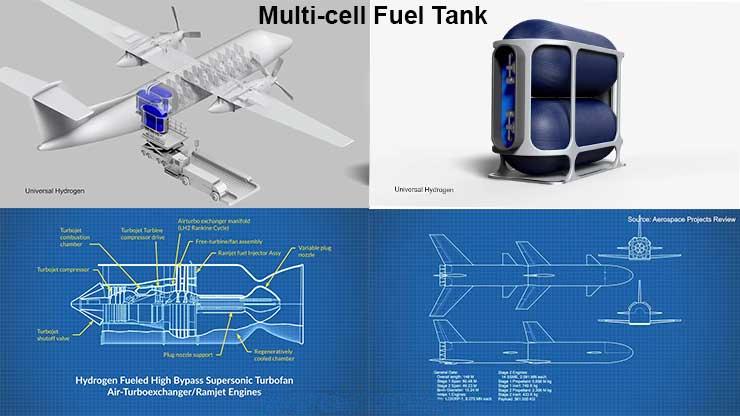

There was a great deal of eternal volume not only for cargo but fuel as well. The cargo deck was modelled after the C-5 galaxy and it was 20 feet high and 20 feet wide in a square shape and 141 feet long, that’s 6×6 (6 by 6) and 42.9 meters for those living outside the USA. The craft would have two engine systems:

Rockwell Star Raker Engine-1:

First, It was a conventional jet engine specifically a hydrogen-fueled. A high bypass supersonic turbofan air turbo exchanger ramjet engine each with and 40000 pounds of thrust. The space plane also had three hydrogen-fueled rocket engines. Each with 1.06 million pounds of thrust and an ISP (International Space Plant) of 455.

Rockwell Star Raker Engine-2:

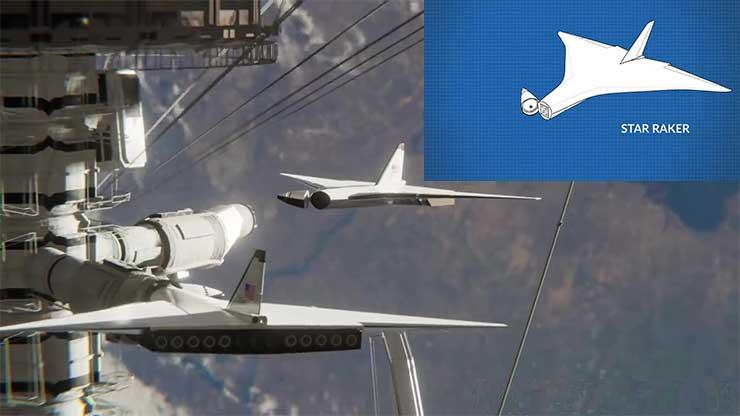

Seconds, enough to get it into that high orbit. This is, how it would all come together? The Star Raker would start its mission with a conventional runway take-off with conventional turbo-fan power. Its ramjets would also act as supercharged alpha burners to help it get into the air. The spacecraft would jettison. Its landing gear and use parachutes to land softly. Which would then be available for the next mission. It would then head to the equator from Florida flying much like a normal plane. This would burn up fuel. It means less for the trip into orbit. The Rockwell international countered that future versions would have in-flight refueling.

The aircraft would rise to a high altitude, dive down to build up speed, and then turn upwards to reach a height of 29 miles. After rocket engines speed up to Mach 7.2, it would shut them down and execute a Ho-man transfer to reach an orbit point 556 kilometers above the earth.

The Star Raker or should I say, spacecraft now in orbit. It would open its nose to release the payload directly. It would have a system of rails on board that could quickly mate with the rails of the space station and funnel out cargo. The nose that would swing out would have a two-level crew compartment. It consists of a flight deck and seating. On the upper level, there are electronics, life support, and emergency supplies. On the lower deck, you can find more emergency supplies.

The missions did not include sleeping quarters. Flights were not expected to be very long. An airlock at the back provides cargo bay access mid-flight or after landing. It got up to space. Leaving orbit would be fairly typical of the same flight path of the shuttle that we have today.

The Star Raker would perform a low gamma flight path angle. Its high alpha angle of attack re-entry de-acceleration profile at approximately Mach 6. Then lower the alpha attack angle to the appropriate angle. It gets the maximum drag to ride at the highest speed. A plane takes off at Mach 0.85 by opening its inlets and starting the air breather engines. It performs a powered flight to a landing field land on a runway.

The Star Raker could cruise for 300 nautical miles or 555 kilometers at a subsonic speed. It makes two landing attempts. In case the first one didn’t succeed, according to the SPS program we outlined before. They would need 1100 flights each year to support the SPS program. It about one launch of the star raker every 8 hours.

Advantages of Rockwell Automation – Star Raker:

The Star Raker had several advantages over the space fighter. It is including the ability to land at any airport that could hold a 747 or C-5 galaxy. It only needed a runway of about eight thousand to fourteen thousand feet long. 2440 to 4270 meters for landing and take off respectively. It could pick up cargo by itself at some regional airport. It can be transported to the space launch site without special means of transportation.

Disadvantages of Rockwell Automation – Star Raker:

Industry experts expressed that, the Rockwell Star Raker represents the direct thrust of future aerospace development. Why didn’t they build this miracle machine despite diligently developing important technologies in the past?

In the end, the star raker never really came close to the development. It was a change in political power in the United States. The REAGAN administration and the price of oil plummeting that made. This expensive SPS satellite ring concept seems very silly and very expensive without the need to start manual work.

Design Issues in the Rockwell Automation – Star Raker:

There were some issues with the Star Raker design:

Issue No.1

It was less capable due to unfeasible materials technology. The plane is even today there hasn’t been a successful spaceplane design. With the United States only coming close with rockets launched from flying aircraft. Therefore, it is confusing if even the concept itself could work.

Issue No.2

The 2nd problem Rockwell Star Racker was the fuel. The Star Raker had to be powered by liquid oxygen and liquid hydrogen. Two things you don’t find lying around at many airports if any across the United States. Tons of infrastructure would need to be built to support the refueling of these giant space planes. Engineers suggested that the creation of this profitable industry would require the development of supporting infrastructure.

The designers insulted injury by adding a geometrically complex multi-cell fuel tank to the space plane. They put together a series of conventional cylinders side by side to make a boxy fuel tank. It held them together by a web of internal tension to keep them in place during flight. This concept could have provided greater volume and incredibly lightweight. There don’t seem to be any spelling or grammar errors in the text. It reads correctly as follows. But many questions arose as to whether such a fuel tank was even possible to design and build.

Flash forward to the year 2021 we can’t help. Such a mission for an alternative fuel source would have been very useful. In the age of global warming and the climate emergency. If we had near-infinite power in orbit around the planet. It would have been incredible for transporting energy around the world. We made fossil fuels obsolete overnight. America would have shared the SPS power network with its allies around the world. If the rest of the world doesn’t take action to prevent further climate calamities.

Conclusion:

That idea may be a little utopian and is quite probable. They would have just turned the satellites into some sort of orbital microwave cannon. The Rockwell international star raker would have been the ideal craft for many other missions. A fleet of them being available for various tasks at a moment’s notice is eye-watering for this space fan. Imagine the other orbital stations we could have built the use for deep space mining. For all the never-built concepts that I have covered in this article. This one hurts the most and makes me the saddest of them all. We hope you people would like and enjoy this amazing information, regarding “A Great Flying Machine The Rockwell Automation | Star Raker“.

If you people have any problem with this written material. Please leave a comment or contact me via email.

Thanks for reading !

Acknowledgment:

A special thanks to foundandexplaine, wikipedia, Google, and aerospaceprojectsreview which helped me in collecting the relevant data.